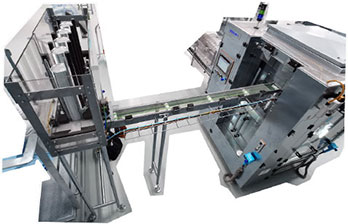

? Completely stainless steel structure

? Storage table with double optoc ensuring controlled feeding of rolls

? Storage capacity of 150 rolls of 2.02 ends

? Unwrapping unit by means of static knife in conjunction with rollers.

? Paper bin collector

? Sentinel system, for detection and automatic removal of reversed ends

? Detection and automatic removal of reversed ends

? Easy operating and cleaning

? Minimal effort required for maintenance

? 24-hour operation – 7 day a week.

? Maximum safety for operating staff

Machine dimensions: 5000mm(length)×1000mm(width)×1600mm (height)

Can-ends: Aluminium SOT/Steel CDL/superends

Can-ends per hour: max. 200,000

Roll capacity: Max. 6 rolls/min.

Packing of rolls: GB 009-643/A and TYL Spec

Compressed air: 6 bar (g)

Compressed air consumption: 200 NI/min.

E-Power connection: 380V; 3 phase; 50 Hz and Earth

Total connected power: 2.5 kW

Net weight approx.: 1500 KG

Range of voltage: 380 V ±15%

TYL300 feeds can end with a maximum capacity of un-wrapping 6 rolls per minute, allowing a guaranteed capacity of 120,000 ends per hour, based on a double discharge and double infeed to the downstream seamer or two different seamers.

TYL200 is ideal for feeding lids, as well as round nesting, square, rectangular or oval lids. TYL200 can hold a large inventory of can lids or ends, while feeding them, on demand, to one or multiple production lines. Built for ease of operation and maintenance, it will streamline any filling or can making operation.

TYL-B-100 machine is developed for Tin can lid seamer, which handles the lids with diameter from 70mm-170mm.