? Barcode Reading (ladder + picket fence oriented)

? 2D Data Matrix Code Reading, including QR codes

? Decoration Inspection, including color print quality, ghost prints (double prints), upside-down cans and damages

accurate

Defect size: 2×2-3×3mm

struggle

Detection evaluation: 99-99.9%;

error rejection rate: 0.1-0.01%

speed

60000-90000 cans/hour

type of packaging

Jars/bottles/various round products,

the best size of cans: φ99mm and φ127mm, and height <200mm

Clearance requirements

One jar diameter space

Machinery Information

The total assembly weight is 500kg,

specification: 1300 × 1300 × 1802 mm

Certification and grade

CE certification. Directive: 2006/EC;

Electromagnetic gestures: 2004/108/EC

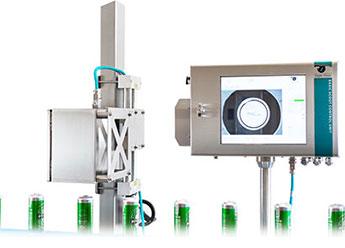

The 360° Can Inspection module is a highly accurate, reliable and proven Mix-Up & Integrity Detection system for lithographed & labeled cans. The system integrates multiple functions hybridly in one system:

? Barcode Reading

? 2D Data Matrix Code Reading

? Decoration Inspection, including damages

In addition, extra relevant modules can be connected. For example Empty Can Inspection (inspects can interior and flange), Seam Inspection, and/or Cap Inspection.

The system is used by (Infant Formula) Can Fillers, Can Makers, and similar products with challanging reflective surfaces, such as Bottles, Jars and soup/sauce Cups.

Functionalities:

? Barcode Reading (ladder + picket fence oriented)

? 2D Data Matrix Code Reading, including QR codes

? Decoration Inspection, including color print quality, ghost prints (double prints), upside-down cans and damages

Options:

? OCR Code Reading

? Label positioning

? Empty Can Inspection (interior + flange)

? Seam Inspection

? Cap Inspection

? Code Reading of batch/date codes

Features & Benefits

? Automatic learning functionality

? Short changeover time using product library or MES input

? Compact footprint available

? No mechanical adjustments needed

? Proven standard system

? Random product orientation

? Simple installation to the line

? Stainless steel hygienic frame

? Network connection

? Remote access connection

? Storage of statistics and pictures

? Very operator friendly user interface

? Easy maintenance due to absence of moving parts

Applications

? Automated vision inspection

? Can inspection

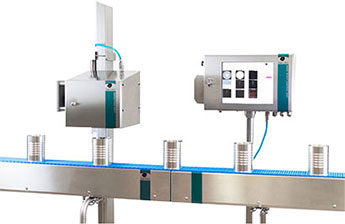

The Code Reading module inspects ink-jet, laser and thermotransfer codes on various packaging types, including (infant formula) cans, beverage cans, labels, cartons, film, foil and PET bottles. The Code Reading module checks if codes are present, complete, readable or correct.?

The Empty Can Inspection system is able to detect defects quickly and accurately on the flange, bottom and the inner sidewalls of the can.

Leaking products is one of the most common risk issues. At first it frustrates the production process by leakage and pushed off loose (snap)caps . And worse, it has effect on the product integrity and customers health.