? Crown corks

? Turn/twist caps

? Sport caps

? Snap caps

? Easy caps

? General caps

Accuracy: 0.5-2mm2

Peak value: 99-99.9%;

False rejection rate: 0.1-0.01%

Speed: 90000 bottles/hour

Packing type: glass bottle

Total weight: 60kg;

Certification and level: CE certification

Specification: 380×380×300mm

Low Voltage Directive: 2006/95/EC;

Electromagnetic steering directive: 2004/108/EC

Leaking products is one of the most common risk issues. At first it frustrates the production process by leakage and pushed off loose (snap)caps . And worse, it has effect on the product integrity and customers health.

We have optimized Cap Inspection set-ups used for:

? Crown corks

? Turn/twist caps

? Sport caps

? Snap caps

? Easy caps

? General caps

Functionalities:

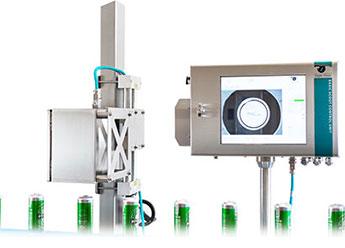

The Cap Inspection can inspect for one or more features:

Cap Positioning (canted caps, scew caps, double caps, cap height, temper evidence, bullnose caps, flip caps)

Cap Mix-Up (color, artwork, code, embossing)

Cap Orientation (aligned with the product packaging or labels)

Thanks to the modular set-up you can select and combine the features that are important to your line.

Options:

? (360 degree) Label Inspection

? Code Reading of batch/date codes

? Fill-Level Inspection

Features & Benefits

? High Speed inspection available, up to 90.000/hour

? Extra color sensitivity available

? Short changeover time using product library or MES input

? Compact footprint

? Proven standard system

? Simple installation to the line

? Stainless steel hygienic frame

? Network connection

? Remote access connection

? Storage of statistics and pictures

? Very operator friendly user interface

? Easy maintenance because of no moving parts

Applications

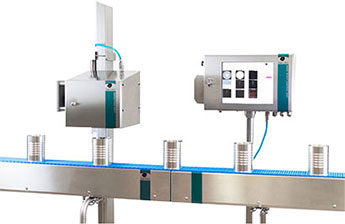

? Automated vision inspection

? Can inspection

? Leak detection

? Seal integrity

The Code Reading module inspects ink-jet, laser and thermotransfer codes on various packaging types, including (infant formula) cans, beverage cans, labels, cartons, film, foil and PET bottles. The Code Reading module checks if codes are present, complete, readable or correct.?

The Empty Can Inspection system is able to detect defects quickly and accurately on the flange, bottom and the inner sidewalls of the can.

Lab measurements equipment is highly accurate, but based on sampling a selection of the entire production.