? Seam dents

? Droops/Vee

? Cut seam

? Knocked down flange

? Double seam

? Incomplete seam

? False seam

? Tight/loose seam

? Cut down seam

? Seam spinner/turned corner

Lab measurements equipment is highly accurate, but based on sampling a selection of the entire production. Because of that defective seams can be detected too late and inconsistently. Or worse; by the customer.

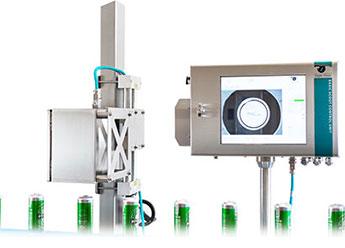

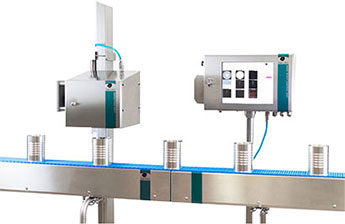

The in-line Seam Inspection module inspects the complete seam around the can. The module is positioned in-line to inspect 100% of the produced cans, non-destructively. Various can sizes and can shapes are inspected without any product handling. The inspection is available for high line speeds.

Functionalities:

? Seam dents

? Droops/Vee

? Cut seam

? Knocked down flange

? Double seam

? Incomplete seam

? False seam

? Tight/loose seam

? Cut down seam

? Seam spinner/turned corner

Options:

? Empty Can Inspection, for inspection inside and flange of empty cans

? 360° Can Inspection, for inspection of exterior of cans (mixed-up lithograph, damages)

? Code Reading, including ink-jet code, barcode, QR code, OCR code

Features & Benefits

? In-line inspection of seam

? Inspects 100% of the produced cans

? Non-destructive

? No product handling needed

? High speed available (up to 90.000 products per hour)

? Different can sizes and shapes, including round and rectangular cans

? Modular expandable with other inspection modules

? Network connection

? Remote connection

? Storage of statistics and pictures

? Short changeover time

? Simple installation to the line

? Stainless steel hygienic frame

? Very operator friendly user interface

? Easy maintenance due to absence of moving parts

Applications

? Automated vision inspection

? Can inspection

? Leak detection

? Seam inspection

The Code Reading module inspects ink-jet, laser and thermotransfer codes on various packaging types, including (infant formula) cans, beverage cans, labels, cartons, film, foil and PET bottles. The Code Reading module checks if codes are present, complete, readable or correct.?

The Empty Can Inspection system is able to detect defects quickly and accurately on the flange, bottom and the inner sidewalls of the can.

Leaking products is one of the most common risk issues. At first it frustrates the production process by leakage and pushed off loose (snap)caps . And worse, it has effect on the product integrity and customers health.